The discovery and refinement of boron nitride nanotubes (BNNTs) stand as a transformative advancement in nanotechnology, promising significant improvements in aerospace, electronics, and biomedical fields.

The patent US8206674 B2, granted in 2012 to the National Institute of Aerospace and NASA, reflects an innovative synthesis process enabling the scalable production of BNNTs.

These nanotubes exhibit unique physical and chemical properties, offering extreme durability, thermal resistance, and electrical insulation—ideal for applications demanding high-performance materials.

Background of BNNTs

Boron nitride nanotubes were first successfully synthesized in the mid-1990s, but limitations in production scalability hindered their broader application. BNNTs are structurally similar to carbon nanotubes (CNTs) but comprise boron and nitrogen atoms, which impart distinctive properties like thermal stability up to 900°C and high resistance to oxidation.

Such attributes make BNNTs highly attractive in sectors like aerospace, where materials must withstand extreme temperatures, provide radiation shielding, and maintain structural integrity under stress.

Despite these desirable traits, challenges in BNNT production remained. Conventional synthesis methods, such as arc-discharge and chemical vapor deposition (CVD), produced BNNTs with inconsistent properties and in low yields.

The invention covered by this patent addresses these issues by introducing a novel method that enables continuous BNNT growth, significantly improving scalability and commercial viability.

The Invention Process

The patented synthesis method is centered on creating a reliable boron vapor source mixed with nitrogen gas under controlled conditions. The boron vapor is generated from a solid boron target, heated to its vaporization point using a high-powered laser. The process involves:

- Boron Vapor Generation: A laser heats a boron-containing target to form boron vapor, which then reacts with nitrogen gas to create BNNTs. The laser method is precise, allowing for the high temperatures required to sustain boron vaporization without contaminating the nanotube structure.

- Nitrogen Gas Mixing: Nitrogen gas is introduced at pressures above atmospheric levels, creating an environment where boron and nitrogen atoms readily interact to form BNNTs. This method enables the creation of high-quality nanotubes with consistent structures.

- Nucleation and Growth: The boron and nitrogen mixture forms BNNTs at a nucleation site on the target’s surface. As these tubes grow, they align into fiber-like structures called “streamers” that can extend for centimeters.

This alignment is vital for harvesting longer, uninterrupted nanotubes suitable for industrial applications.

This process has demonstrated growth rates of approximately 10 centimeters per second, a substantial improvement over previous methods. The technique’s scalability holds promise for industrial production, positioning BNNTs as viable materials for high-stakes applications like structural components in spacecraft and medical implants.

DETAILED DESCRIPTION OF THE INVENTION

The synthesis of few-walled boron nitride nanotubes (BNNTs) is a breakthrough innovation driven by a process of controlled surface nucleation, creating what are called “streamers” that resemble flapping kite tails as they grow along the vapor flow in a synthesis chamber.

The process uses a laser to generate boron vapor, which is then combined with nitrogen under high pressure, resulting in the continuous formation of BNNT fibers.

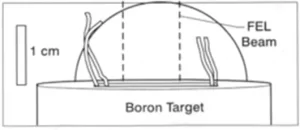

This synthesis is achieved using a 1 kW free electron laser (FEL) beam directed vertically downward onto a rotating boron target, about 2.5 cm in diameter. This setup, combined with a nitrogen gas flow at ambient temperature, produces a highly controlled environment for fiber growth.

The laser continuously drills into the target, creating a cavity that extends roughly 2 cm deep. As the laser heats the bottom of this cavity, boron vapor begins to rise, mixing with the nitrogen to initiate streamer formation at the edge of the cavity.

The nitrogen pressure is maintained at around 12 bar, as elevated pressure is critical for producing BNNTs; without it, only boron droplets form and solidify rather than turning into streamers.

Each streamer forms quickly, reaching lengths of over a centimeter within milliseconds, and some detach from the target, swirling in the chamber. These streamers, collected on surfaces like wire coils, resemble spider silk with a medium matte grey hue. They are also highly resilient, capable of being stretched multiple times their length before returning to their original form.

High-resolution electron microscopy reveals that each streamer comprises interconnected bundles of BNNT strands that can deform under load and spring back. Visible in the structure are nanoparticles of boron, which range from 5 to 80 nanometers, further indicating the precise material structure achieved.

Transmission electron microscopy (TEM) and energy-filtered transmission electron microscopy (EFTEM) analyses provide insight into the nanotubes’ crystalline structure. Most BNNTs in the streamers are around 3-5 nm in diameter with walls that are typically double-layered.

The electron energy loss spectroscopy (EELS) confirms their composition, showing boron and nitrogen peaks that align with hexagonal boron nitride bonding, with an ideal boron-to-nitrogen atomic ratio of 1:1. Additionally, EFTEM imaging highlights bright cores of boron nanoparticles with crystalline BN coatings, further validating the structural purity and consistency of BNNTs in these streamers.

The laser-induced creation of these fibers involves an initial phase where boron metal is ablated by the laser, drilling into the target. As this cavity deepens, it begins to act as a radiant chamber where boron reaches its boiling point, emitting boron vapor into the nitrogen-rich chamber.

Observations reveal that streamers form near the cavity’s upper edge where the vapor mix is ideal for BNNT nucleation, aided by aerodynamic forces within the chamber. These aerodynamic forces are essential for BNNT growth, as they ensure that boron vapor flows steadily along the inner surface, supplying the necessary conditions for continuous nanotube formation.

Unlike carbon nanotube (CNT) synthesis, which typically requires a catalytic surface, BNNTs in this process grow spontaneously from nucleation sites in the boron/nitrogen mixture. The absence of a catalytic requirement simplifies the BNNT production process, eliminating the need for additional compounds that complicate CNT production.

Here, growth is primarily dictated by surface asperities—small irregularities on the boron target surface that act as initial growth sites for BNNTs, facilitating root growth and eventual streamer formation.

One of the challenges in expanding this synthesis method is the high temperature required to vaporize boron at the necessary pressures. While laser heating is effective, it is costly, and other heating techniques, such as RF induction or hydrogen-oxygen flames, may offer more economical solutions.

Current tests with the 1 kW FEL achieve a boron vapor flow of about 35 grams per hour, which scales up to 350 grams per hour with a 10 kW laser. Achieving this level of production is a significant step towards the commercialization of BNNTs, where consistent, high-yield outputs are essential.

In conclusion, this synthesis method offers a scalable approach to producing high-quality BNNTs, with potential applications in areas requiring durable, high-performance materials. The BNNT production process underscores the possibilities of laser-based manufacturing in nanotechnology, enabling the growth of fibers with unique properties while addressing scalability challenges for future industrial applications.

Importance of Patenting the Invention

The patent for BNNT synthesis plays a crucial role in fostering further innovation and protecting intellectual property. In industries like nanotechnology, where R&D is costly and time-intensive, patents ensure that inventors can safeguard their investments and capitalize on their innovations.

- Protecting Innovation: The BNNT synthesis patent prevents competitors from replicating the process, encouraging research organizations and companies to continue investing in BNNT technology without fearing immediate imitation.

This exclusivity period provides a competitive advantage, enabling the inventors to develop the technology further and explore new applications.

- Encouraging Commercialization: Patents highlight the importance of commercialization for transitioning inventions from laboratories to real-world applications. The patent incentivizes manufacturers and investors to fund further development, knowing that the technology is legally protected.

This financial backing is often critical for scaling production and addressing technical challenges that arise when moving from prototype to production.

- Stimulating Further Research: By disclosing the synthesis method, the patent also serves as a foundation for additional research. Other scientists and engineers can build upon this knowledge to develop complementary innovations or improvements.

The balance of protecting the invention while allowing public access to its technical details is key to advancing the field as a whole.

The Potential of BNNT Applications

The synthesis of BNNTs has opened doors to multiple applications across industries. Key properties, such as high thermal conductivity, electrical insulation, and structural strength, make BNNTs uniquely suited for use cases that demand reliability in harsh conditions.

Some potential applications include:

- Aerospace: BNNTs’ lightweight and heat-resistant characteristics can replace traditional materials in spacecraft, reducing weight and improving fuel efficiency. Additionally, boron’s radiation-absorbing properties make BNNTs ideal for shielding against cosmic radiation.

- Electronics: BNNTs are excellent insulators with potential in developing miniaturized, heat-resistant components for electronics, where high-power applications require materials that can operate in high-temperature environments without degrading.

- Medical Field: BNNTs could revolutionize implants and tissue engineering due to their compatibility with biological tissues and resistance to wear. Their structural properties enable the creation of robust yet lightweight prosthetics and implants that integrate well within the body.

Challenges and Future Research Directions

While the patent lays the groundwork for BNNT production, there are challenges to address before BNNTs can achieve widespread adoption:

- Cost Reduction: Laser heating is an effective but costly method. Future research could explore alternative heating mechanisms, such as induction heating, that offer similar temperatures but at lower costs.

- Scale-Up for Industrial Use: Producing BNNTs at the kilogram or ton scale is necessary to meet industry demand. The existing method has demonstrated continuous fiber production, but scaling this up without sacrificing quality or increasing costs is a primary focus for ongoing research.

- Environmental Impact: Ensuring that BNNT production processes are environmentally sustainable is another priority. The high energy required for laser heating and the use of pressurized gases have ecological implications that must be addressed to make BNNTs a truly sustainable innovation.

Conclusion: Patents as Catalysts for Technological Advancement

The patented synthesis of BNNTs represents a significant leap forward in nanotechnology, with the potential to impact various high-performance fields. Patents are invaluable in this process as they not only protect the inventor’s work but also lay the foundation for commercial adoption and further innovation.

For BNNTs, the patent assures both inventors and investors that their contributions are safeguarded, fostering an environment conducive to high-stakes, long-term R&D.

In summary, the invention and patenting of boron nitride nanotube synthesis underscore the essential role of patents in advancing technology.

They provide a competitive advantage, encourage investment, and catalyze research—essential components for innovation in any industry. As BNNT technology continues to evolve, this patent will serve as a cornerstone, enabling new breakthroughs and expanding the boundaries of what is possible in material science and beyond.